Deep reinforcement learning for production scheduling

Initial Situation

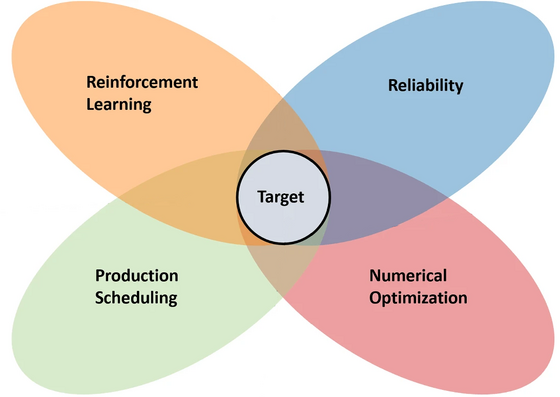

Production scheduling is a research area characterized by computationally complex combinatorial planning problems. It includes methods for solving problems where available resources must be efficiently allocated to production processes. With increasing product variety and shorter production and innovation cycles, the complexity of the problems and the demands on the scheduling methods increase. On the one hand, schedules must enable robust and quality-conscious production and meet KPIs such as lead times and resource consumption. On the other hand, scheduling must be able to cope with abrupt changes in production conditions, such as resource bottlenecks or machine failures. A promising way to meet these requirements is machine learning, in particular Deep Reinforcement Learning (DRL). In our research, we investigate the use of DRL to solve both standardized scheduling problems from research and real-world planning problems from industry.

DRL for Job Shop Scheduling

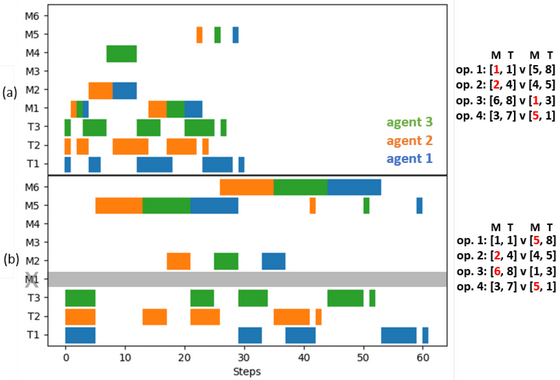

A key scheduling problem we address is the job shop scheduling problem (JSSP), where jobs are processed on a given number of machines, with each job visiting the machines in a different predefined order. In this context, we investigate multi-agent approaches to increase flexibility with respect to different JSSP sizes (e.g. number of machines) or different reward functions and action spaces, which can be used to improve standard DRL training methods. In addition, we study variations of the problem, such as flexible JSSPs, where not only the optimal order of operations must be determined, but also a choice can be made between different machines that can perform an operation. The focus of our research is on the appropriate response to unforeseen events, such as the arrival of new orders in production or machine failures.

Schlably Framework

An important milestone of our daily research is the development and release of the Python-based software framework schlably for DRL-based JSSP (documentation at Read the Docs). With schlably, empirical experiments with individual solutions can be developed, executed, evaluated, and compared with existing benchmarks.

Deployment for Real Planning Scenarios

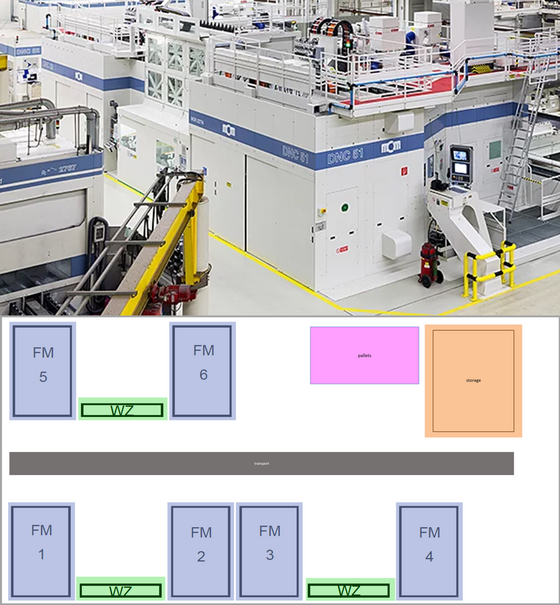

In our research, we investigate the use of the methods in real-world applications for the control and planning of production process chains in digitized shop floors. The main research goals are the creation of a data base by collecting, preprocessing and providing process relevant data as well as the development and testing of deep learning-based planning and control systems that suggest appropriate response strategies in case of disturbances and resulting deviations from the planned process flow.