Visual inspection

In the "Visual Inspection" focus area, we are dedicated to the application of deep learning and computer vision to support industrial inspection processes. Our research approach is to adapt the latest methods from the state of AI research and develop new solutions to make visual inspections more precise, efficient and transparent.

Data Generation

Large amounts of curated image data are required to train robust AI models. Many models therefore use so-called backbones, which are pre-trained on extremely large but unspecific data sets such as ImageNet. However, these backbones are not sufficient for the transfer to specific inspection scenarios and must be enriched with high-quality images.

For this enrichment we use DOME -- our solution for automated data generation. This makes it possible to capture objects from different angles within a few seconds. With over 1900 individually controllable LEDs in a hemispherical arrangement, we can simulate various illumination scenarios as they occur in real production processes. The trained AI models for quality inspection are robust against typical changes in the color spectrum and uneven illumination with shadows.

Quality assessment and error detection:

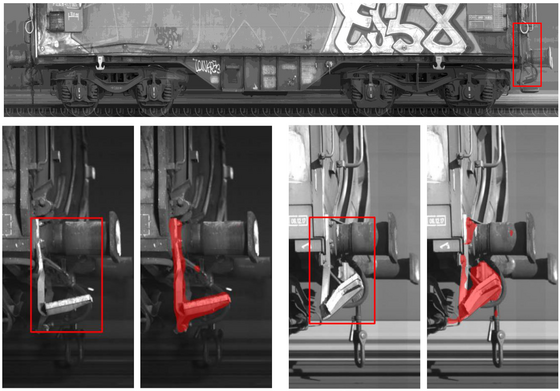

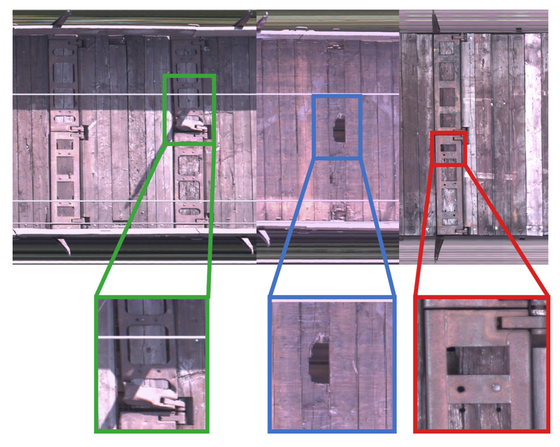

Our goal is to develop methods for precise quality assessment and defect detection in industrial production processes based on image data. By using advanced models such as vision transformers and normalising flow methods, we focus on the reliable detection of anomalies and the identification of defects.

Dealing with real conditions

The challenges of visual inspection in real production environments require scalable and adaptable solutions. We develop multi-level modelling pipelines that are capable of efficiently processing large and high-resolution image data. In doing so, we are researching the generalisation of deep learning methods in order to make the models robust against different environments and disruptive factors. Another focus is on the explainability and visualisation of the results in order to strengthen confidence in the technology and enable continuous optimisation of the models.