DOME

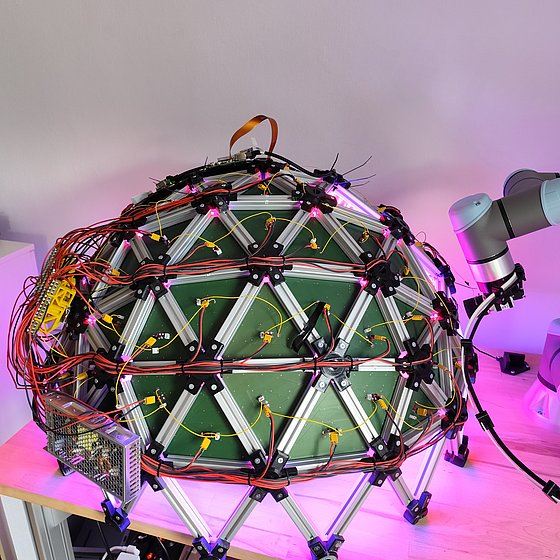

Exterior view of DOME: assembled circuit boards clamped in an aluminum frame.

Large amounts of image data are required to train robust AI models. Many models therefore use so-called backbones, which are pre-trained on extremely large but unspecific data sets such as ImageNet. However, these backbones are not sufficient for the transfer to specific inspection scenarios and must be enriched with high-quality images. For this enrichment we use DOME - (Dynamic Object Illumination for Multi-Perspective Image Data Acquisition) - our solution for automated data generation.

Construction

Interior view of DOME: the object is fixed in the center of a controlled rotating plate.

At the heart of DOME is a hemispherical dome with over 1900 LEDs installed on circuit boards to illuminate the interior. These have three color channels to cover the entire color spectrum. In addition, the LEDs have a channel for neutral white light (4500 Kelvin), which simulates the lighting conditions in typical production facilities. The outer framework consists of aluminum profiles in the geometric arrangement of an icosahedron, which approximates the shape of a sphere as closely as possible and holds the light sources in place.

Two actuators are used for the multi-perspective recording. The angle around the horizontal plane is realized by a rotatable plate, in the middle of which the object to be examined is installed. The angle across the vertical plane is achieved by moving the camera using a robotic arm.

Data Generation

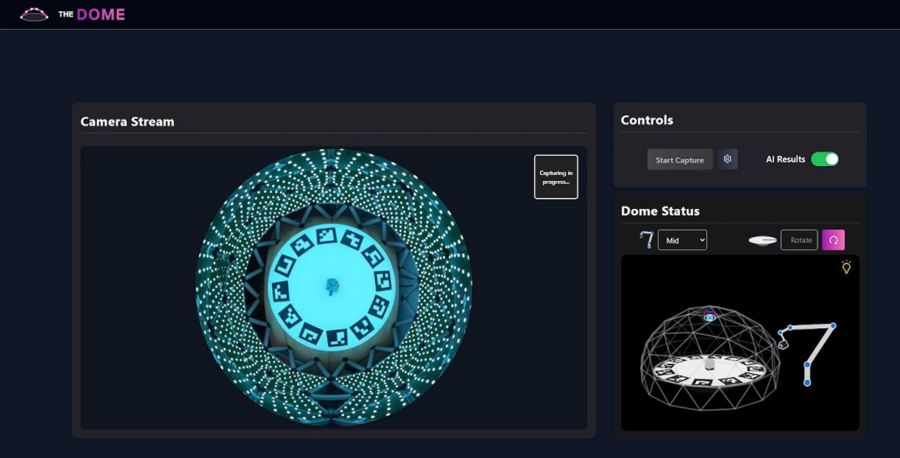

In an interaction between the actuators, the controller for the LEDs and the cameras, data is recorded with different illumination scenarios that cover different light intensities and color spectra. For this purpose, the object is continuously rotated around the horizontal plane and recorded in images at adjustable intervals. Thanks to the strong illumination and short exposure times, we still achieve high-quality images with negligible motion blur at up to 1080 images per minute.

AI-based Defect Detection

Anomaly detection: Identification of a faulty component of the assembly.

Models for anomaly detection are trained on the basis of extremely large but unspecific data sets such as ImageNet and the data generated by DOME in the highest quality and specifically aligned to the object to be inspected. For this, we rely on real-time capable models such as PatchCore and EfficientAD. For applications with greater variance in terms of the position and orientation of the inspected object, we also incorporate information from CAD models. Defect detection is real-time capable and can therefore be optimally integrated into ongoing quality assurance operations.

Graphical user interface for controlling the individual DOME components and visualization of the recording process in real time.